- Venjakob

- Drying technology

- Infrared dryers

Infrared dryers from Venjakob

Long-, medium- or short-wave – for optimized surface quality

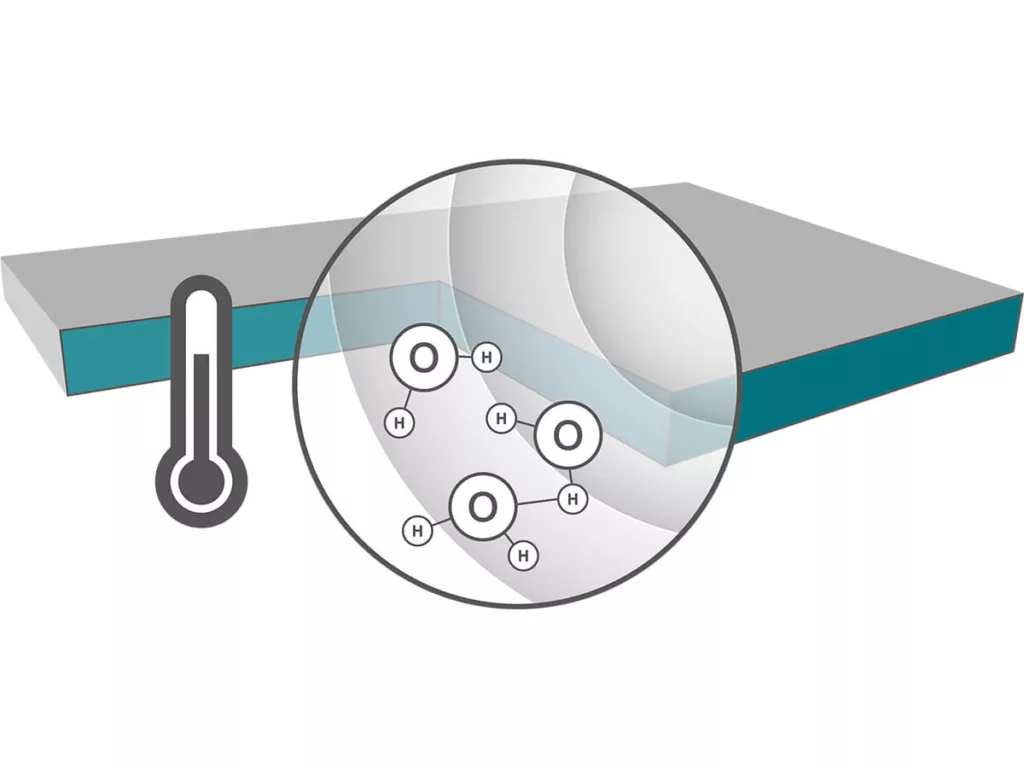

How do you improve the surface quality of your products while reducing your drying times? Through clever drying. With Venjakob infrared dryers. The IR process combines surface evaporation with targeted heat application to the interior of the coating layer. Both effectively prevent premature closing of the surface, so that the coating material dries very quickly and evenly from the inside out. The result: brilliant surface quality without skin or bubble formation. Coating material drying through infrared technology is particularly suitable for temperature-sensitive workpieces.

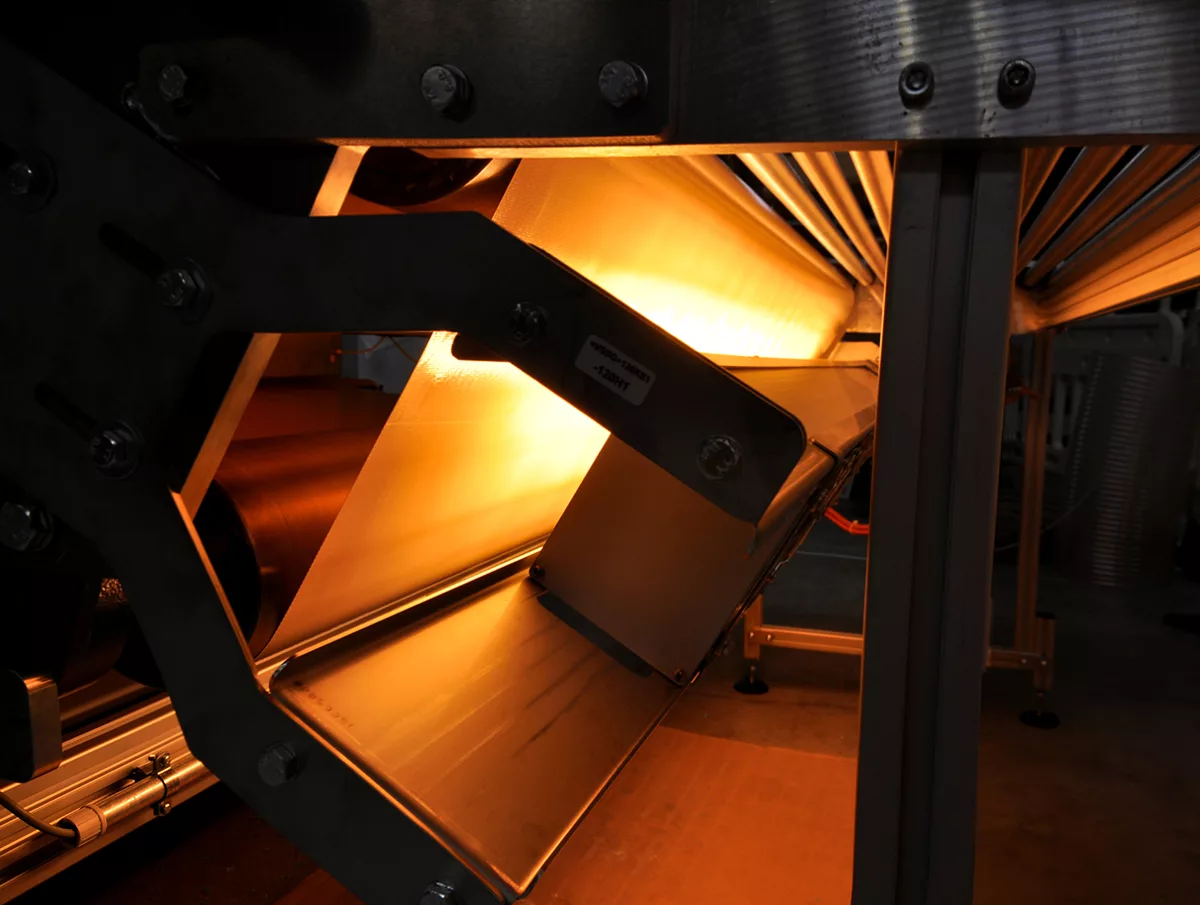

Future-proof through modular design – Venjakob infrared dryers

Is infrared drying a worthwhile solution for you? Of course this depends on whether your production processes are generally suited to this method. Whether the workpieces and coating materials are right for it – and whether there are better methods. But if the process is suitable for your requirements, our infrared dryers are sure to be a future-proof investment. They are easily accessible and modular in design, so you can choose your layout freely and expand as you grow. This means: You can stay flexible because our Venjakob infrared dryers are easy to convert – to different workpieces, materials and/or coatings. And if you want to expand your plant, that's no problem either.

Application examples

Combined for optimal function – infrared dryers plus other processes

Sometimes combining processes does the trick. The effect of infrared drying can sometimes be further optimized by combining it with other drying processes. When and where, for which coating materials and which workpiece materials, remains dependent on your specific system design. The main thing is: At Venjakob, we are happy to advise you – and sometimes you will end up with not just one process, but two, if this helps optimize your production.

SPECIALLY DEVELOPED FOR WATER-BASED COATINGS - OUR DRYERS WITH OPTIMIZED INFRARED RADIATION

Our in-house development VEN DRY OIR ® is a flat-flow evaporation channel with optimized infrared technology - specially designed for drying water-based coatings. This dryer, with its defined climate in the evaporation channel, achieves the best results in any weather. That is exactly why it is used primarily in the wood and furniture industry. It combines extremely short drying times with exceedingly low fiber swelling. The gentle energy input reduces shrinkage cracks and blistering because it keeps the coating layer open. And this system is sure to fit wherever you need it as it doesn't need much space to achieve optimum surface results for you with its optimized infrared radiation.

For preheating, drying and curing – the process

Depending on its exact application, IR technology can complete a variety of tasks:

- Preheating: even before the coating process, in order to improve the drying behavior of the coating applied to the workpiece.

- Drying: When IR technology is integrated into hot-air drying systems, the additional energy input significantly accelerates drying.

- Hardening: IR radiation improves cross-linking of the coating material.

For different coatings and materials – the areas of application

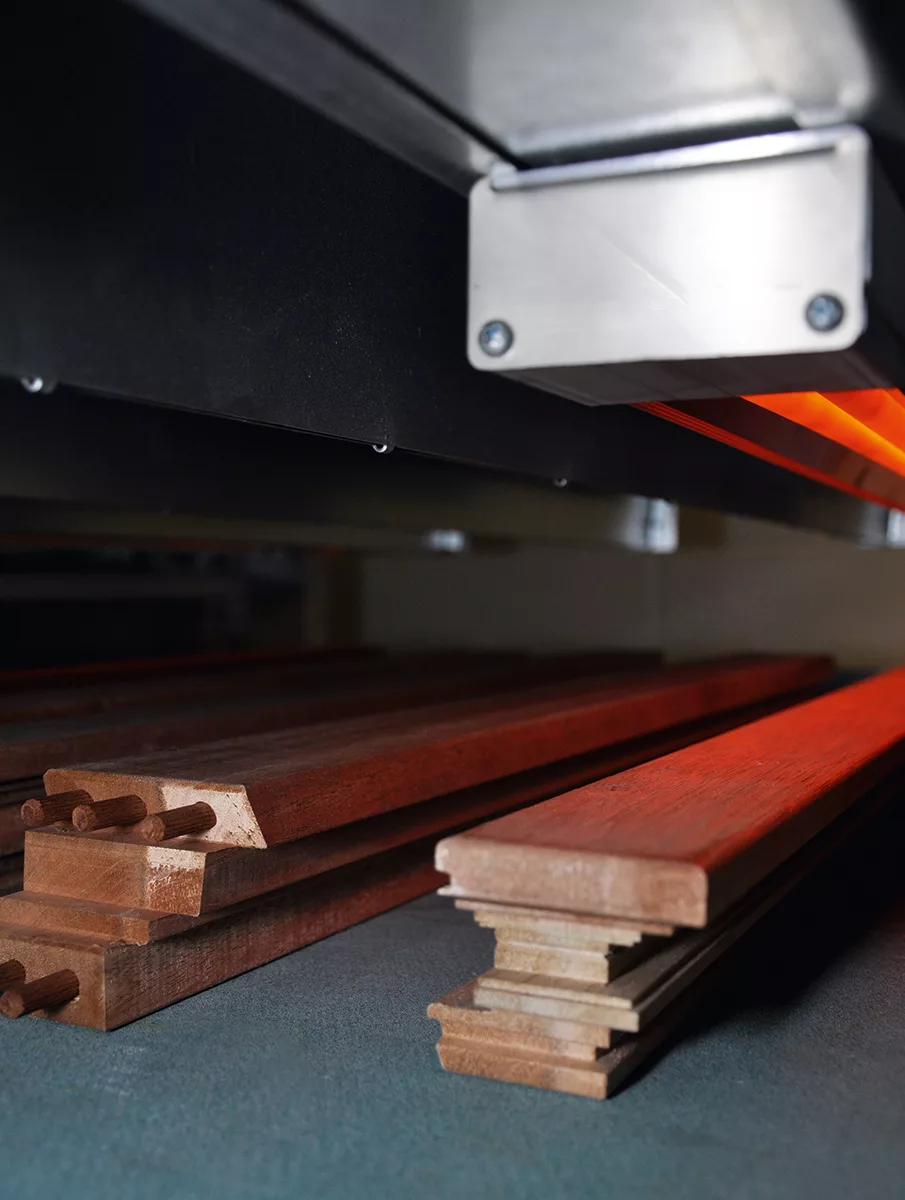

Venjakob IR drying systems are used in all industrial sectors as stand-alone equipment, integrated in lines or combined with other drying technologies. Their gentle action guarantees the best results when drying:

Coating materials

- Water-based coatings and stains, dispersions

- Solvent-based coatings

- Powder coatings

Workpiece materials

- Wood

- Plastic

- Metal

Fast and efficient – the advantages

Venjakob IR dryers contribute significantly to the acceleration of your production processes – if your production requirements allow their use. The lamps used are highly efficient and precisely adapted to the absorption spectrum. The operating point can be fine-adjusted. Workpieces preheated in the dryer dry more thoroughly, more homogeneously and faster. After coating, the infrared radiation ensures that the freshly applied coating particles crosslink quickly and cure optimally. This also eliminates the need to set down and stack workpieces for drying. Both, rapid crosslinking and drying on the one hand and elimination of a process step on the other, reduce drying times and speed up your processes. And thanks to the long service life of our extremely low-maintenance lamps, your enjoyment will last: As a rule, our lamps last more than 10,000 hours. That’s a lot of time for drying.

Your contact

Interested? Then let's talk! About your custom-designed system with integrated infrared drying.

Gert Grosse Deters

General Industry|Automotive

Christian Streit

Wood|Building Materials