- Venjakob

- Surface pretreatment

- Activation process

- Flame silicification

Flame silicification and flame pyrolysis with Venjakob

Common and highly effective – a hot method for activating surfaces

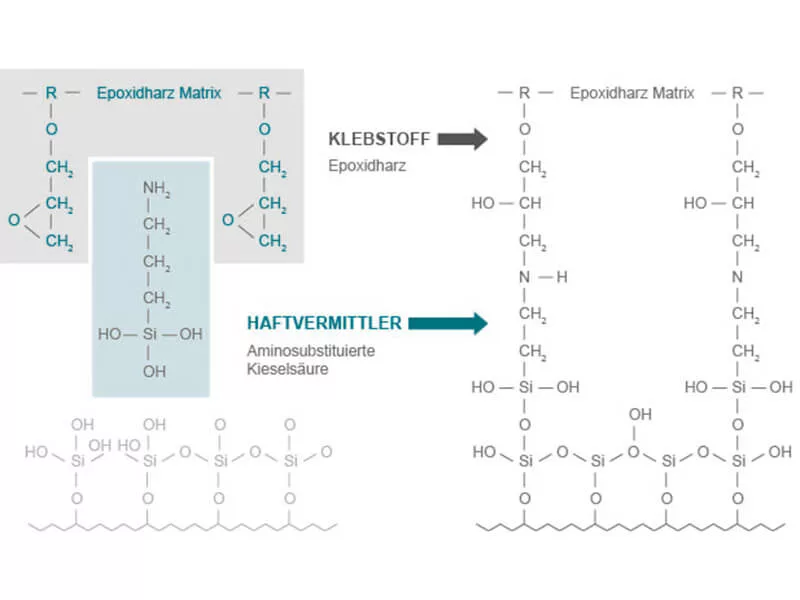

Flame treatment is a common pretreatment process. It is used to increase the adhesion strength of surfaces to make it easier to apply adhesives, finishes and print media. Further significant improvements in adhesive strength can be achieved by separating a reactive silicate layer through flame pyrolysis. On metal, glass, ceramics and plastics, this process generates surface energy that makes it easier to coat workpieces.

And how does this flame silicification work?

The principle is simple, as we always say. Provided the chemistry is right. We’re not kidding! The principle of improving adhesion through flame silicification is based on chemical processes, but all you really need to know about those is that Venjakob has mastered them to perfection. Just like everything else related to your plant.

Applications for flame pyrolysis | flame silicification

Venjakob activation plants for flame pyrolysis are used in a wide range of industries, such as:

- Automotive

- Plastics technology

- Glass and solar industry

- Printing industry

- Construction industry

- Aerospace technology

- Optics

- Sensor systems

- Electronics

- Medical technology

Flexibility in plant engineering

At Venjakob, we manufacture the surface pretreatment systems for flame pyrolysis and flame silicification in modular design. The advantage of this method is more flexibility for you, because we supply the module either as a complete machine unit, or on existing transport systems – just as you request.

Your contact

Our in-house technical center makes it possible to test processes under realistic conditions. This includes flame silicification. Simply let us know what you need and feel free to involve your material supplier. We will find a solution – together.

Gert Grosse Deters

General Industry|Automotive