- Venjakob

- Dry ice cleaning from Venjakob

Dry ice cleaning with Venjakob

Dry ice cleaning is a highly effective method for cleaning surfaces without leaving residues prior to coating and finishing. Venjakob offers solutions for this process that fit seamlessly into the overall industrial surface finishing process. This method is effective, hygienic, gentle and at the same time thorough. It protects both the material and the environment. So as you can see, there are plenty of reasons for considering this method when choosing the ideal pretreatment process.

How does dry ice cleaning / snow blasting work?

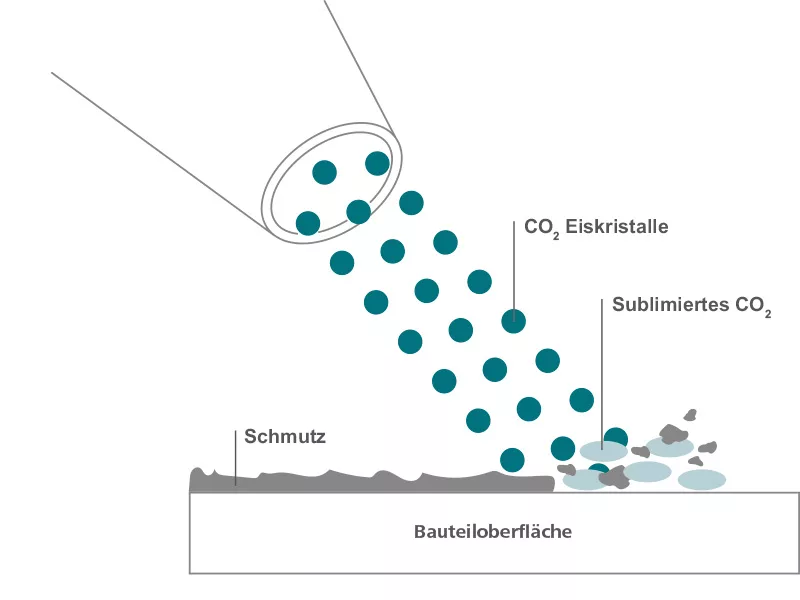

To put it simply, there are two different types of dry ice cleaning. First of all, there is cleaning with dry ice, secondly there is snow blasting. Both processes are compressed air blasting processes, differing only in the fact that, in snow blasting, liquid carbon dioxide is constantly fed from CO2 low-pressure tanks or rising tube cylinders, while in dry ice cleaning dry ice must be fed in ready-to-use form. In snow blasting, therefore, the carbon dioxide solidifies in the process itself, whereas in dry ice blasting the dry ice is already present before the process. This formation of solid particles in the compressed air blast is also referred to as the conversion of liquid carbon dioxide into a snow-gas mixture. Snow blasting, in turn, has two different variants. The first is a less abrasive method that is particularly suitable for cleaning surfaces with fine textures and sensitive surfaces. The second variant uses larger snow particles produced in an agglomeration chamber with a significantly stronger abrasive effect. Nevertheless, both snow blasting methods are less abrasive than cleaning with dry ice and therefore gentler in removing deposits. In principle, both methods have the same effect: The blasting agent applied to the surface with compressed air breaks up the dirt on the surface with its crystalline pellets and sweeps away the dirt particles. The effect of the compressed air is further enhanced by the fact that snow and dry ice become gaseous again on impact and increase in volume.

Operating principle of CO2 cleaning

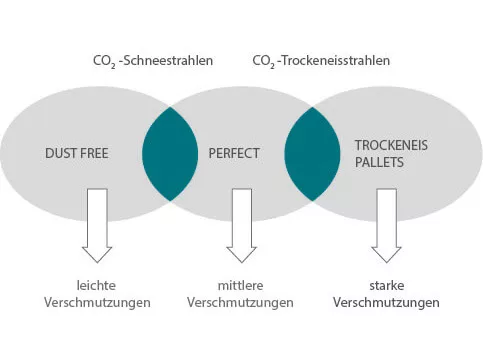

The two variants of CO2 cleaning - snow blasting and dry ice blasting - cover the entire range from light through medium to heavy contamination.

In dry ice blasting, the pellets hit the layer that you wish to remove under high pressure, freezing the dirt on the component surface and breaking it up. A process called sublimation turns the crystals gaseous, thereby increasing their volume and intensifying the effect of the compressed air: the dirt is literally blasted away.

Dry ice blasting machine versus CO2 snow blasting machine

When you are faced with the choice of which cleaning method should precede the coating process, you get to decide between a dry ice blasting machine or a CO2 blasting system. It should be noted at this point that there are also other processes for surface pretreatment. However, Venjakob has decided to focus on CO2 blasting systems in this context. We offer these as part of custom-designed complete solutions or as stand-alone solutions. In each case this depends on our customers’ needs and the space available at their facilities.

Surfaces and materials

Dry ice cleaning and snow blasting are used, for example, on building materials for facade cladding or on metal workpieces such as sheets and plates. Other areas of application include glass – for example, architectural glass, glass needed for solar panels, and glass for residential applications. Plastics used in the manufacture of small and large electrical appliances, household technology and cars are also usually cleaned with dry ice before being coated. For all these applications, Venjakob can provide numerous references in a wide variety of areas of application.

The advantages of the process

The advantages of dry ice cleaning and CO2 snow blasting are obvious. Contamination is removed from surfaces in a way that is gentle to materials and the environment, fast and effective, germ-free and hygienic, without the use of chemicals – using only carbon dioxide. Yet another crucial factor is the user-friendliness of the process, the cleaning intensity of which can be specifically adapted to your process. Both manual operation and fully automatic solutions are possible. Which of these variants makes more sense for you usually depends on your production and the quantities requiring coating. The process quality is particularly evident in mass production of workpieces with large surfaces that involves integrated coating or gluing processes. The process runs reliably and flawlessly – even in continuous operation. And it can be integrated flexibly in your plant. It can also be installed on flat surfaces or in robotic systems. And the machines are wear-free and ice-proof. Formation of condensate by the dry ice cleaner is not to be expected. In short: Dry ice cleaning or snow blasting is suitable for the vast majority of companies with a coating process, not least because of the small space required. At least in those many, many fields that do not require any other type of pretreatment.

Processes tested and simulated many times over at our technical center

What distinguishes us as a provider of coating solutions for a wide variety of industrial manufacturing processes is the uniqueness of our concepts. We are guided strictly by what is required: what is the best system for our customer's needs in each specific case? That is the question we have to answer from scratch every time we receive an order. We are not interested in selling our customers something they do not want. What matters to us is close collaboration based on trust. But as previously mentioned, what underlies this is a comprehensive view of a coating task that requires a solution. We understand this coating task as a process, at the beginning of which is loading or feeding of an automated conveyor. The next step is pretreatment, the cleaning process. This is where dry ice cleaning or snow blasting is located, although alternative methods such as dust removal/ionization or metal degreasing should also be mentioned here, as well as other abrasive or activation processes. Only then comes the actual coating and finishing process, which might also involve staining or adhesive application. Finally, there is drying, then stacking. This is accompanied by exhaust air purification, which is crucial not only for the environment, but first and foremost for the health of your employees. We would like you to know that all the steps just described are parts of the process. None of them is fixed, and each can be adapted separately. We simulate the interaction of all these steps at our technical center in Rheda-Wiedenbrück. It is not the only one of its kind. A counterpart can be found at our company Nutro Inc. in the USA.

Have we convinced you? Are you interested in dry ice cleaning?

You think blasting with dry ice or snow blasting is the perfect method for you to remove dirt from the surfaces of your products before coating? Then get in touch with us! We will be happy to supply you a stand-alone solution for pretreatment. And if you need a complete system, we will be happy to develop it for you.

Your CONTACT

Interested? Then let's talk! About a special solution for any application – or more generally about the plant that will help you get ahead.

Gert Grosse Deters

General Industry|Automotive

Christian Streit

Wood|Building Materials