Digital and modular: That the paint doesn’t come off tomorrow

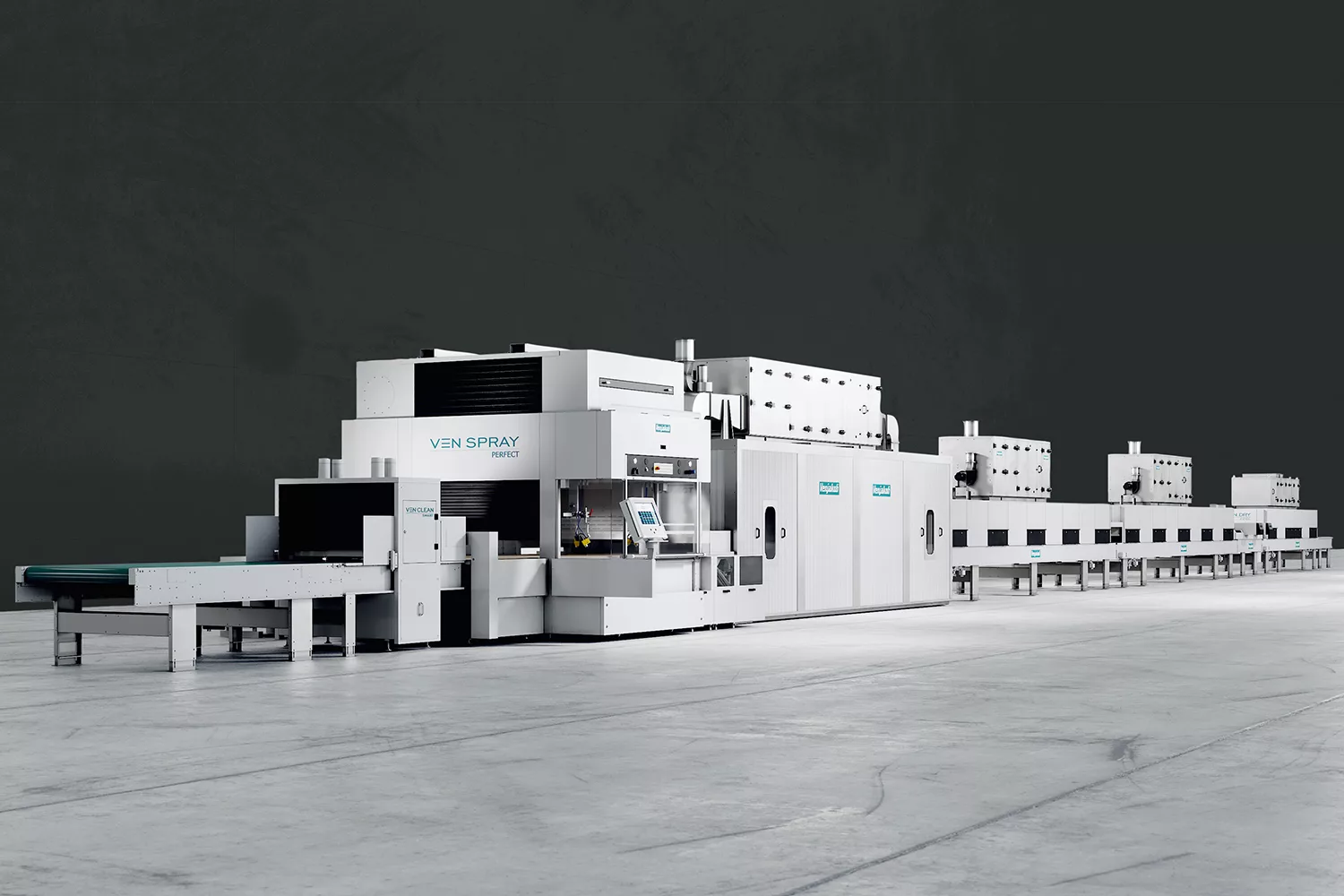

Future-proof coating systems are characterized by economic efficiency and a high degree of flexibility using intelligent control, and digitalized communication systems. The modular concept from Venjakob allows the individual machines to be equipped as needed and can be upgraded with additional functions at any time.

Surface treatment in industrial furniture production is an important, and possibly even the most important part, within the entire production. A lot of money can be spent here and just as much can be saved. Expensive coatings, time-consuming machine cleaning, compliance with environmental regulations and constantly changing trends in materials and coatings require technical equipment that offers the customer required flexibility and therefore investment security for the future.

Overall concept with individual solutions

The overall system concept for surface treatment described here serves as an example of what modern coating systems can achieve. The Venjakob system was developed for coating processes like furniture surfaces, glass surfaces, and special materials. The individual machines – from the preparation of the workpieces, through spray coating, to drying – were optimized with individual equipment and assembled to create a complete system.

Traditional wood coatings, water-based or with organic solvents can be used, as well as UV coatings. The most common coatings for glass surfaces,

2-component polyurethane systems or enamel coatings can be used in the system.

Central control panel for all machines

All relevant system parameters are available via the integrated internal communication system (Ethernet) and can be preselected and set via a central control panel. This enables flexible interaction of all individual components. Each product has its own recipe. Each color can be prepared in parallel with ongoing production and activated within a very short time.

High availability of the system

Regarding the amortization of the investment in the system, Venjakob focused on the greatest possible flexibility of the machines when planning the production line presented here. Entsprechend wurde die technische Ausstattung gewählt. The technical equipment was chosen with a particularly focus on spray coating. The breakdown of the total production time into production and cleaning time is typical for spray coating applications. This defines how efficiently and profitably the system works. The advantages of the modular design are therefore particularly clear with the spray coating system. The customer has the possibility to configure the machine in such a way that a non-stop operation without interrupting, due to cleaning, is possible. Important “time wasters”, such as cleaning the belt cleaning systems, can take place in parallel with production.

Essential: Machine and Process Data

Important information about the processes, the productivity of the system, as well as key data that document the wear and tear are essential for the consistent production quality, the logistical planning, and the maintenance of the system. The advantages of process data acquisition include:

- Characteristic data provides maintenance necessary wear and tear data before the system must be shut down due to a maintenance issue.

- Production management receives reliable data on productivity and can therefore meet the specified goals.

- Material flow and resource planning are easier within the information network because a requirement is identified at an early stage.

- Material flow and resource planning are easier within the information network because a requirement is identified at an early stage.

The surface treatment in 3 steps

1. Cleaning: The preparation of the workpieces

The upstream workpiece cleaning removes contamination from the workpiece surfaces via consumption-optimized, rotating, contact-free blow-off nozzles. The swirled-up particles are collected via an efficient extraction system which is connected to an on-site dust collection system. The cleaning is followed by neutralization of static surface charges on the workpieces via an ionization system. The workpieces leave the pre-cleaning in a clean and charge-neutral state.

2. Spray Coating: Completely Automated Color Change

The spray machine conveys the workpieces via a closed belt system under the spray guns moving perpendicular of the direction of travel. The machine is equipped with an automatic color change system. Together with the central control system, the color change takes place automatically. An application-adapted exhaust system, in conjunction with a sophisticated fresh air supply, enables optimal removal of the resulting overspray. The workpieces are recorded on the infeed side by a workpiece scanner and the machine control system creates a consumption-optimized spray coating program for each spray gun installed. The remaining coating material, that collects in the offset area of the workpiece edges, on the conveyor belt is recovered and cleaned using a patented belt cleaning system. The cleaning system is designed that different water-borne or solvents coatings can run in the system in free alternation. Alternatively, non-stop production can be set up, using external cleaning of the belt cleaning system while production is running. Due to its modularity, the machine is equipped with a high level of production availability, which can be achieved by installing a second washer. The highest energy and environmental standards are observed.

3. Drying System: Freely Configurable

The drying system consists of modules that were process variables like, air speed, temperature and optionally humidity, can be freely configured. The usual drying phases adapt to the coating systems used. Everything is possible: from short evaporation phases to intensive drying phases, supported by infrared heat radiation with subsequent UV curing. The final cooling via a controlled conditioned cooling process, leads to a repeatable and safe overall drying process.

Your CONTACT PERSON