- Venjakob

- Automation

- Conveyor systems | Handling technology

Conveyor systems and handling technology from Venjakob

Optimized, customized, adapted – to perfect your material flow

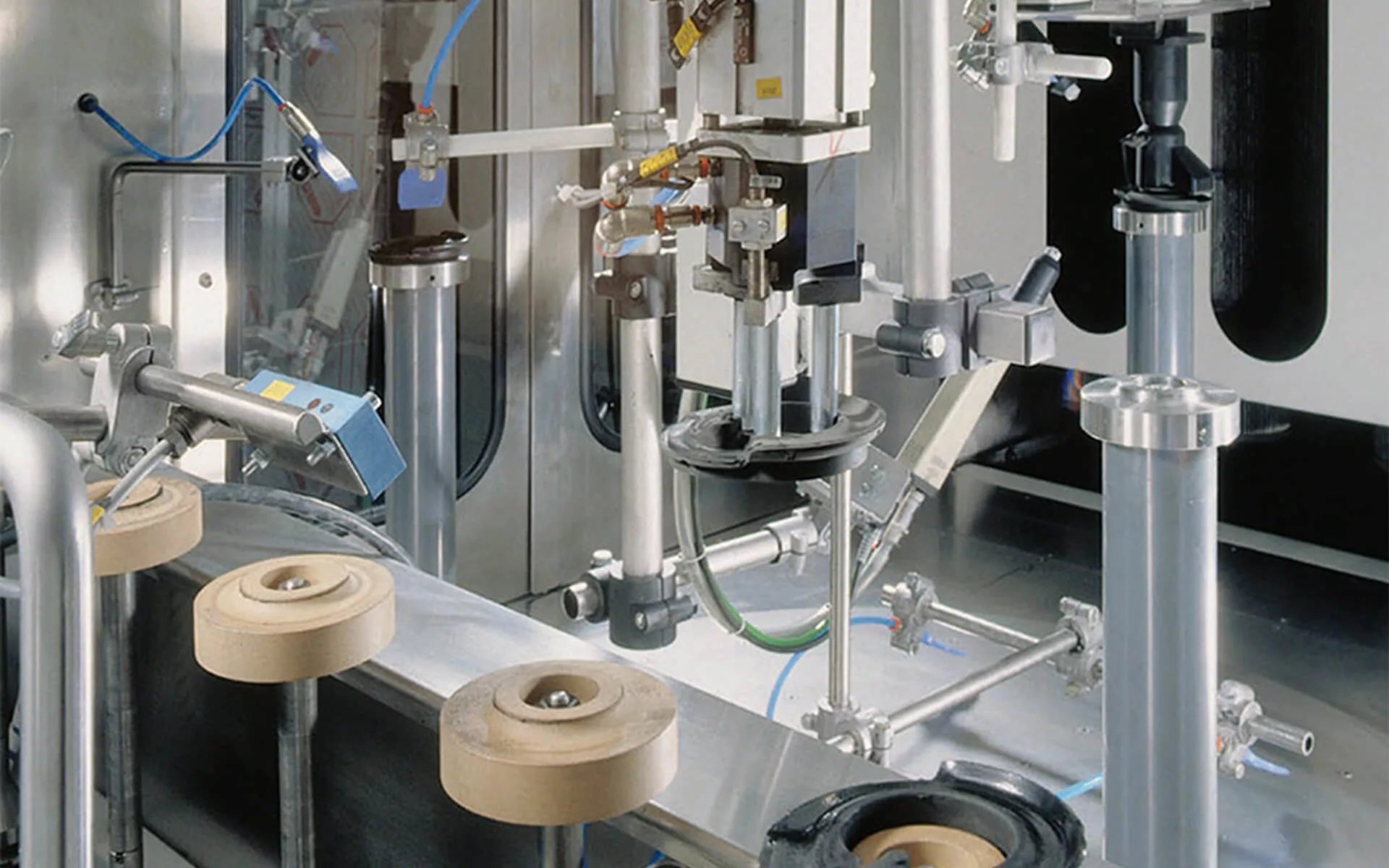

Handling technology and conveyor systems in mechanical engineering control the material flow in your production, all along the line in your coating system. These systems are all about safely and effectively moving your workpieces – no matter the format, the material or the distances being covered. At Venjakob we develop effective transport solutions just for you: Conveyor systems for your entire production line, taking into account all factors – such as short drying distances or maximized conveying capacities. We can even supply these as a single plant. And we always adapt them precisely to your requirements.

Powerful, convincing, reliable – conveyor technology for complex requirements

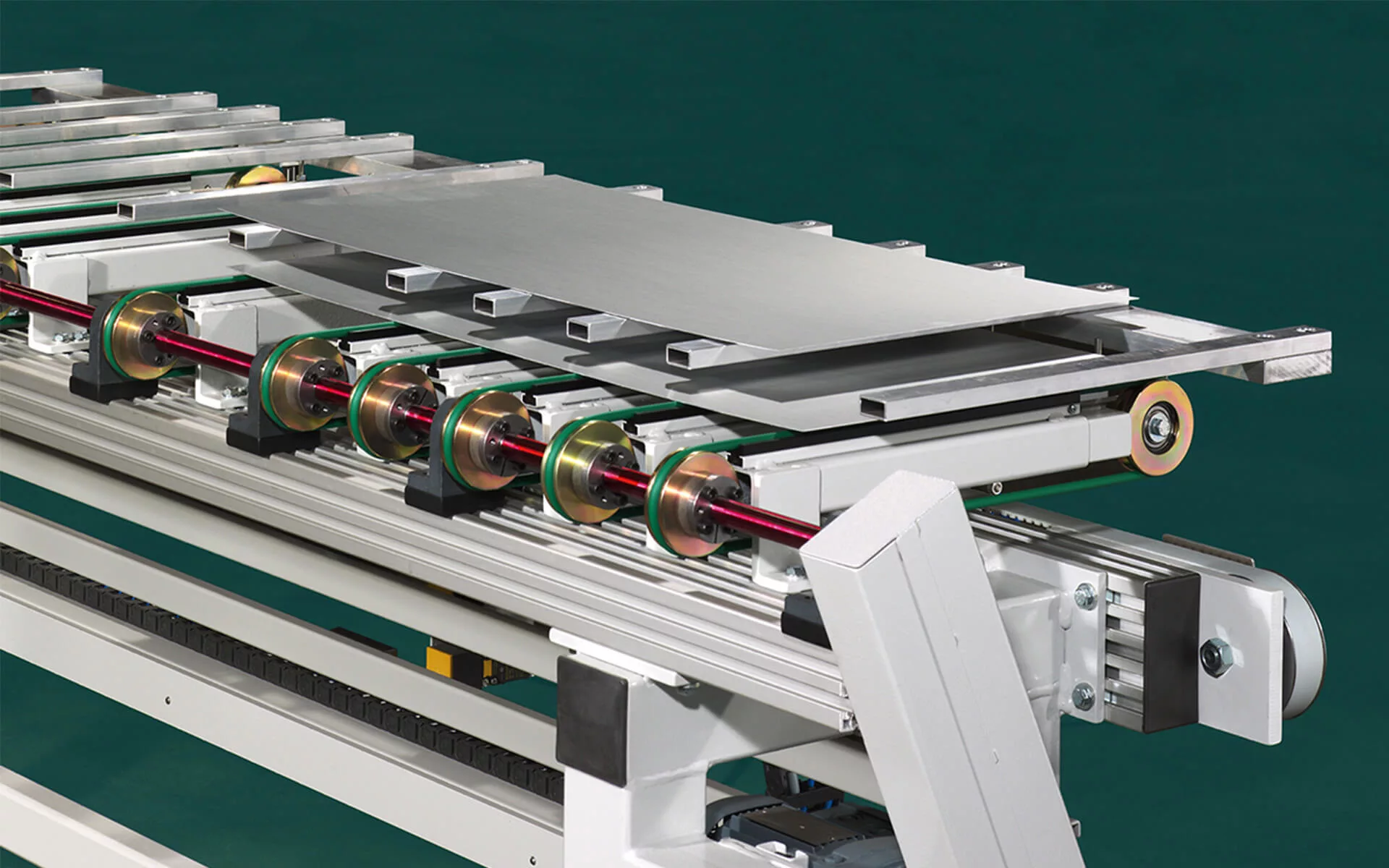

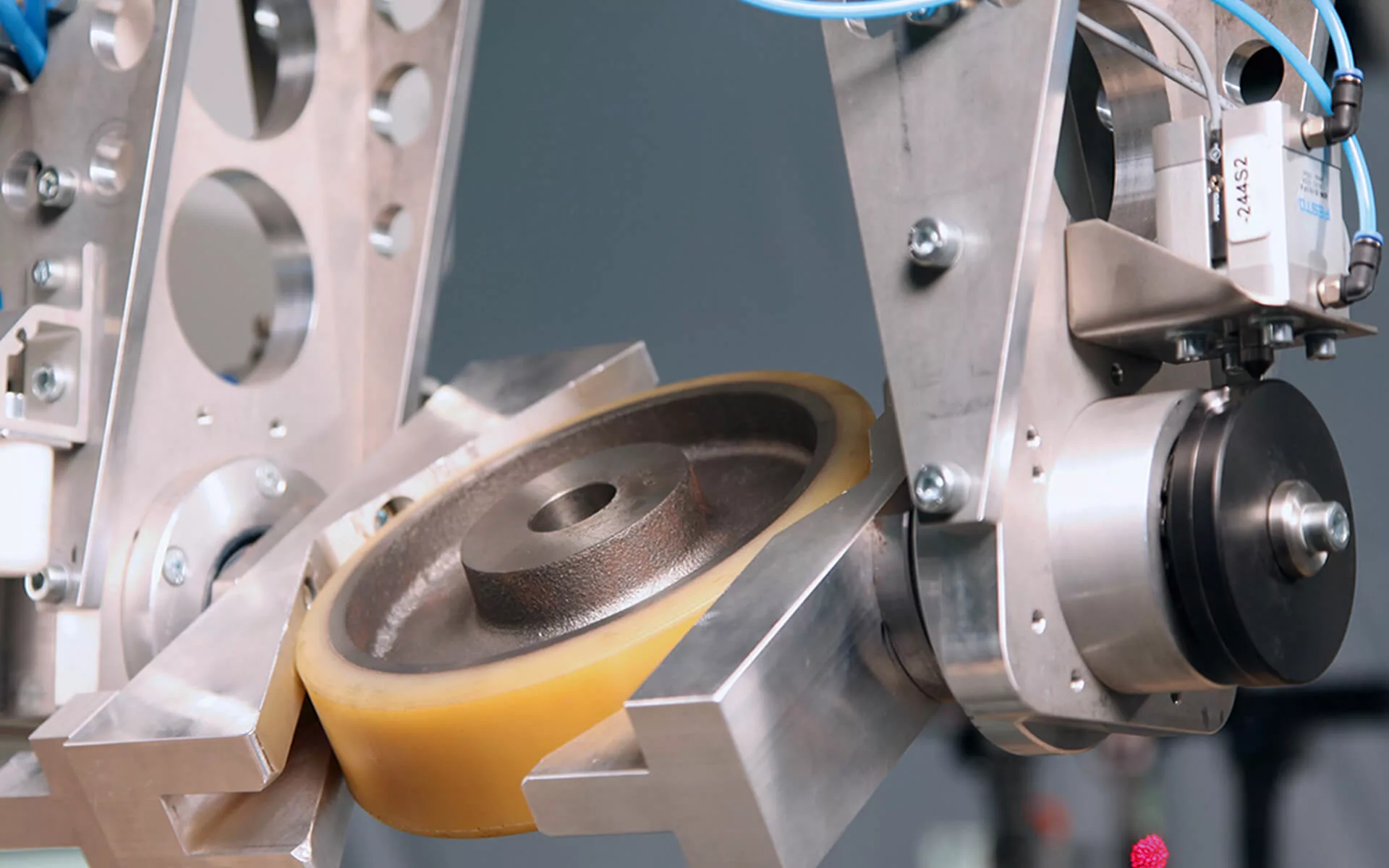

Every production line is different. Sometimes there are curves and bends. Sometimes large workpieces have to be transferred. And the conditions are often extreme. Whatever you need, Venjakob offers you a wide range of powerful and convincing solution components. From continuous conveyors through patented curved transport systems to complex cross transfers, we implement customized solutions for the continuous and reliable transport of your workpieces. If you need a flexible workpiece carrier system, we offer spindle chain, chain-on-edge or skid conveyors for defined process sequences with continuous or clocked transport. All transport solutions are designed for extreme conditions: for example, for temperature ranges up to 450°C (840°F) or even for use in a potentially explosive atmosphere.

Venjakob conveyor systems

- Chain-on-edge and spindle chain conveyors

- Roller transports / roller conveyors with and without workpiece transfer

- Transport curves from 20 to 200 degrees

- Standard, mesh and steel conveyor belts

- Skid conveyors

Safe, professional, optimized – handling technology for perfect handling

For proof of the efficiency of our handling technology, just look at our decades of experience

in plant engineering. Our handling systems will contribute significantly to the professional optimization of your handling process. First and foremost, because – in addition to transporting your workpieces safely and effectively – they create great potential for streamlining your processes through automation and optimization of recurring handling tasks. In short, our innovative solutions are extremely cost-effective, meaning they increase your competitive ability.

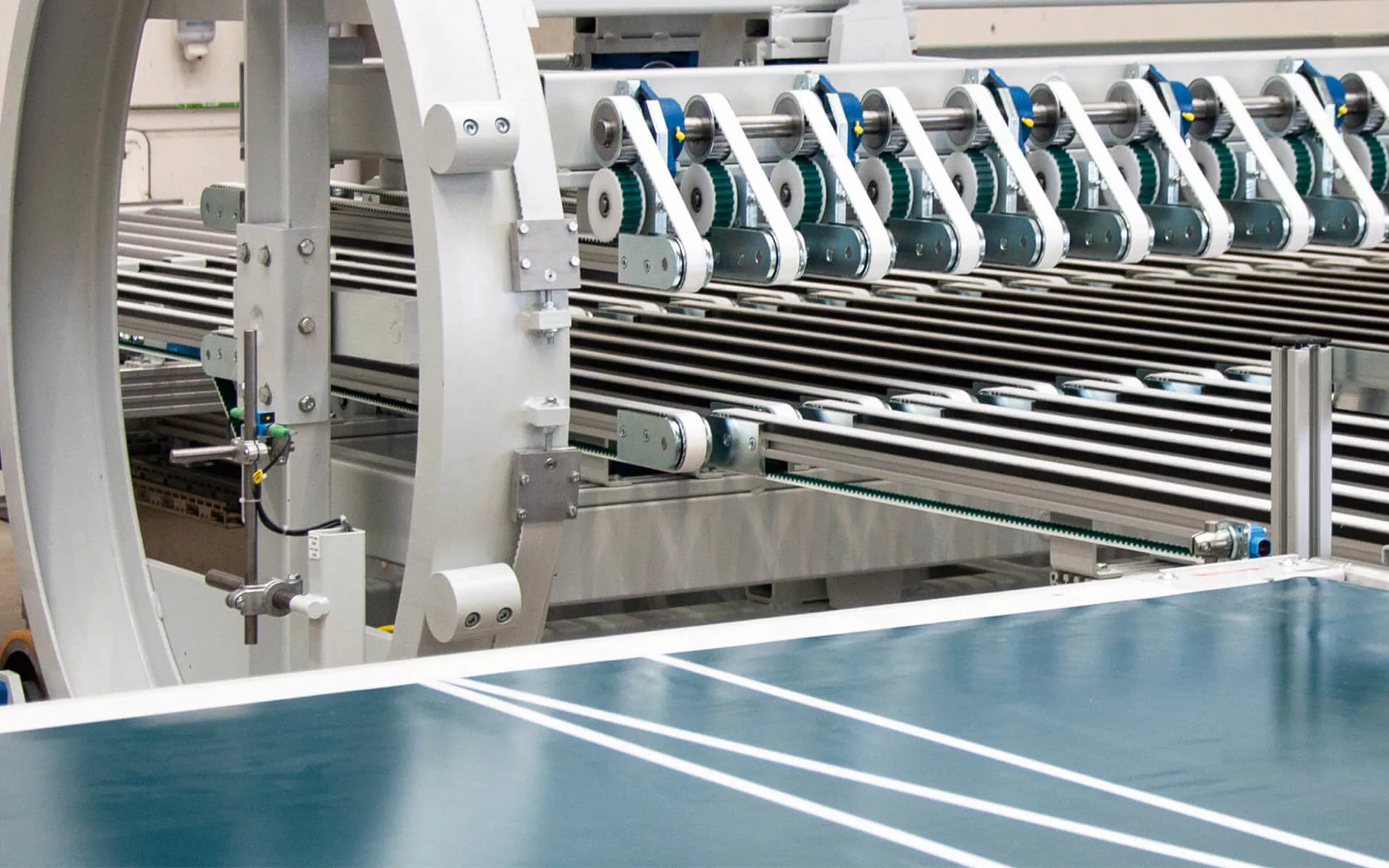

Venjakob handling systems

- Rotating devices (fork, drum and star turners)

- Cross transfer systems

- Collection systems

- Separation systems

- Feeding systems

- Stacking systems

- Workpiece turning devices

- Handling robots

- Fully automatic conveyor systems of various types

Cost-effective, agile, used worldwide – handling systems from Venjakob

Twist and turn things as you like – our handling systems will give you the flexibility to optimize your plant from start to finish. Transferring, stacking, feeding, collecting, separating or allocating – our solutions often perform several functions at the same time. Our conveyor and handling concepts are used in the automotive industry, the building materials sector, the foundry industry, the wood and furniture industry, the plastics industry, the glass, leather, metal and supplier industries. All over the world. Our solutions are custom-designed and tailored to the specific requirements of each application. They are used for individual tasks or integrated in Venjakob coating and finishing systems and dryers. Venjakob coating and finishing lines and Venjakob conveyor and handling technology are perfectly adapted to each other. The industry know-how gained in uncountable projects is what makes Venjakob performance stand out from the crowd.

Your contact

Interested? Then let's talk! About your customized Venjakob conveyor system and handling technology.

Gert Grosse Deters

General Industry|Automotive

Christian Streit

Wood|Building Materials