- Venjakob

- Areas of application

- Construction elements

Finishing systems for construction elements of all kinds

High quality, versatile solutions for windows, stairs, doors and gates

Venjakob specializes in the production of high-quality industrial equipment for surface treatment – and that includes treatment for construction elements. Stairs, doors, gates and window parts are just some examples in the wide range of possible applications. Ultimately, Venjakob equipment can be used to coat anything that needs industrial coating. Years of experience allow us to develop cross-industry solutions. These are not simply coating and finishing systems, they are fully integrated processes that allow you to process any component used in your production. In the field of industrial coating and finishing, we offer you a comprehensive portfolio of systems that allow you to coat materials of practically any shape and size. These are not products, not self-contained systems, they are modules that can be precisely tailored to different requirements, modules that can be systematically combined to form a complete plant – your customized plant.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTypical construction elements

There are many different construction elements. With our systems you can coat practically any of them. We have listed the most common applications here:

- Window components

- Staircase construction

- Sectional doors

- Interior and exterior doors

Gap-free, consistent, flawless – the surface quality

We design systems based on your production requirements. Why do we keep making a point of saying that? That’s easy to explain: You yourself are well-aware of how complex the products are that you produce. And how complex the processes are that you use to produce them. There is a lot to coordinate and adjust. Different product ranges, workpiece sizes, coating systems, throughput speeds, pretreatment methods, drying phases, automation, exhaust air purification, and so, so much more. Sure, you could get yourself some standardized product. But systems tailored to your requirements – like those supplied by Venjakob – run better, faster and offer more options: Our solutions help speed up your operational processes and increase your output of perfectly coated pieces. In consistent impeccable quality. Fast color changes included. With our coating systems, which are individually tailored to your requirements, you will achieve outstanding coating and application results thanks to precise controls and state-of-the-art functions.

Applications

What exactly is the benefit of systems tailored to your production conditions and requirements? Why do we keep making a point of mentioning them? That’s easy to explain: You yourself are well-aware of how complex the products are that you produce. And how complex the processes are that you use to produce them. There is a lot to coordinate and adjust. Different product ranges, workpiece sizes, coating systems, throughput speeds, pretreatment methods, drying phases, automation, exhaust air purification, and so, so much more. Sure, you could get yourself some standardized product. But systems tailored to your requirements – like those supplied by Venjakob – run better, faster and offer more options: Our solutions help speed up your operational processes and increase your output of perfectly coated pieces. In consistent impeccable quality. Fast color changes included. With our coating systems, which are individually tailored to your requirements, you will achieve outstanding coating and application results thanks to precise controls and state-of-the-art functions.

Stairs

Every staircase is different and not a single one of them consists exclusively of steps. To put it simply, there are all kinds of components that have to be coated - in all kinds of colors. And these coatings must be particularly hard-wearing. Thanks to Venjakob's customized solutions, they are. No matter whether you are handling small batches or serial production.

Windows

Venjakob specializes in the production of individual window parts. Window parts - of course that includes a basic window. But it also includes roof windows or facade frame systems. These applications make it necessary to think outside the box to provide a solution for coating corner joints effectively, efficiently and flawlessly. With our systems, these tasks, and any other component coating process, are no problem. Waterproofing, primer or top coat - whatever you need is applied to the product in a lying position with rotation so no side is left out. We supply the entire process, from a single source.

Interior and exterior doors

The edges are where the quality of a finish becomes clear. At Venjakob, we offer processes for edge finishing, such as double coating of the outer edges in a continuous flow or combined roller primer application plus spray coating. Profiled and milled sections can be coated using a surface spray coating system or, for complex geometries, upstream robot systems. And just as we offer solutions for these rather complex applications, we also have many other solutions ready for you - from single door coating to series production.

Sectional doors

Sectional doors for outdoor use are available in a wide range of colors. Venjakob offers the perfect equipment for these. And since outdoor use requires particularly high resistance, 2-component coating systems are usually used in these cases.

Success stories

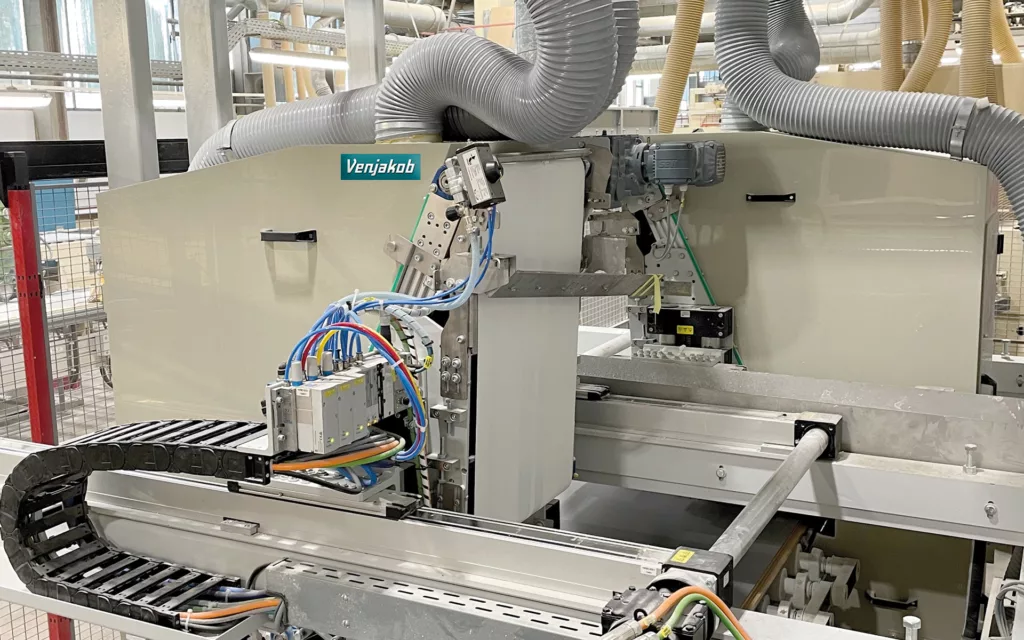

Precise, environmentally friendly, legally compliant – efficient door edge painting

Legally compliant? No, you didn’t misread that. In fact, a special feature of this success story is its contract, which complies with both European law and Anglo-American Common Law. We would like you to know that Venjakob can also support you in these matters. But first and foremost, this story is about a high-precision, automatic, CNC-controlled edge coating system with a modular design. It coats the long edges of functional doors with a double rebate, single rebate or blunt edge on both sides as they pass through the system. A movable jig system that can be adjusted with the aid of recipes protects the door leaves from coating material overspray to the greatest possible extent. This reduces cleaning solution use by 15 to 20 tons per year, which doesn’t just lower costs but also helps protect the environment. An interesting report, isn’t it? Read more.

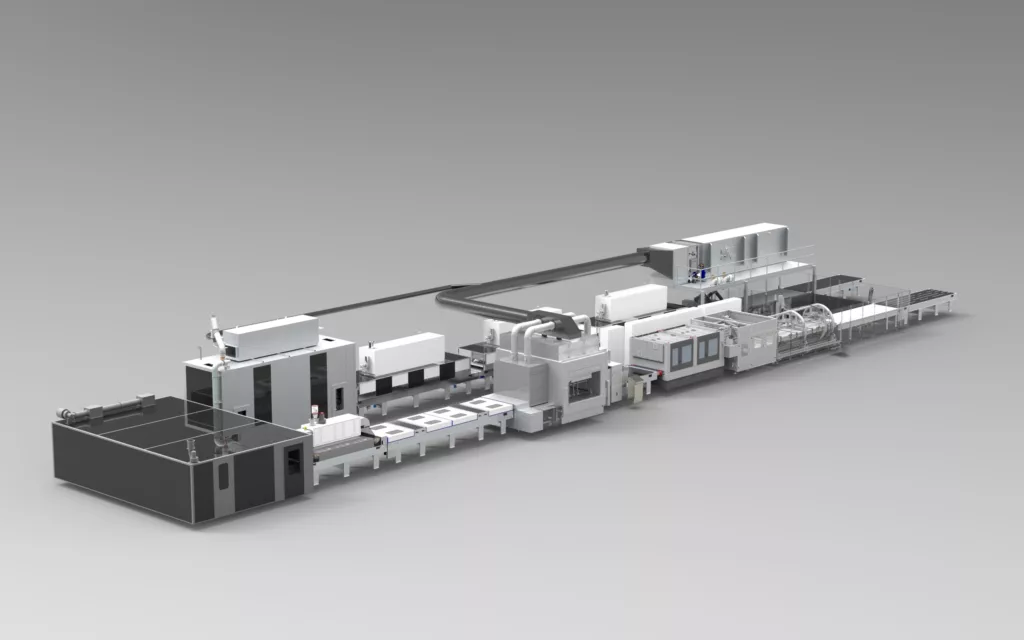

Fast, variable, fully automatic – cost-effective door coating

Good references and successful tests at the technical center convinced RWD Schlatter to entrust Venjakob as general contractor with designing and implementing a cost-effective comprehensive concept for door coating. It was the right choice! The plant, from the conveyor system to the control system to the heart of the plant, the fully automatic spray coating machine

VEN SPRAY PERFECT, and the subsequent drying system coats everything starting at batch size 1: Wooden doors, door panels, lining strips and door bolts.

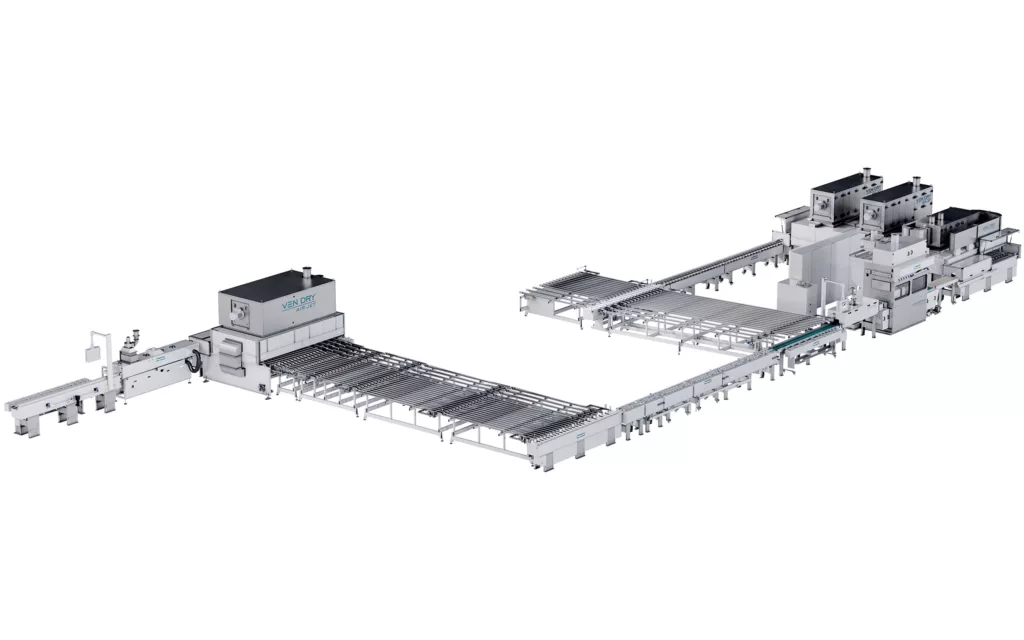

Efficient, comprehensive, sophisticated – window component coating on a grand scale

Fully automatic coating of individual window parts permits fast and flexible production. So it makes perfect sense for production geared to maximum output to rely on a fully automatic coating system. On a Venjakob system. For the Norwegian window manufacturer Gilje Tre, we developed a solution that uses state-of-the-art water-based coating materials to ensure maximum application efficiency and the fastest possible drying process. We also included the complete parts logistics. The long-term advantages are as clear as glass.

Environmentally friendly, fast, convincing – automatic stair coating

If you want to protect the environment, you can make progress step by step to reach a new level without sacrificing quality – and perhaps that is a particularly suitable way for a medium-sized joinery. For this family business, Venjakob designed an automatic coating system that uses environmentally friendly water-based UV coats and water-based stains and features impressively rapid drying times. On top of that, it is fully compliant with EU environmental directives. There you go. Specifically, up. You can find out how we did it here.

Resource-saving, efficient, patented – our sophisticated door coating line

Intelligent solutions are needed for coating in an environmentally friendly and resource-preserving manner while simultaneously increasing production output. Sometimes you even need two of them. For the door manufacturer Garant, Venjakob therefore combined patented technologies with time-tested processes, creating a door coating system that features both a new air recirculation process and state-of-the-art spraying technologies. Read more to find out how much energy this system saves and how much material it recovers.

Roller coating and spray coating in a single pass

The Prüm door factory in Weinsheim (Eifel) is now for the first time using an automated finishing line that combines the previously separate processes of roller and spray coating, including all pre- and post-treatments. This enables the door manufacturer to paint its white interior doors twice as fast as before. The quality has also been further improved as a result.

Customized design from start to finish

Coating, adhesive application, automation and conveyor technology as well as drying systems and exhaust air purification – anything goes with Venjakob’s custom-designed systems. Get an overview of our future-proof solutions.

Reference companies that use our solutions

-

HUGA Holztüren https://www.huga.de/

HUGA Holztüren https://www.huga.de/ -

Interiors Manufacture & Design https://www.interiors-mnd.com/cs/

Interiors Manufacture & Design https://www.interiors-mnd.com/cs/ -

Jeld Wen https://www.jeld-wen.de/de-de

Jeld Wen https://www.jeld-wen.de/de-de -

RWD Schlatter https://www.rwdschlatter.ch/

RWD Schlatter https://www.rwdschlatter.ch/ -

Anton Bruder http://antonbruder.de/

Anton Bruder http://antonbruder.de/ -

Fertighaus Weiss https://fertighaus-weiss.de/

Fertighaus Weiss https://fertighaus-weiss.de/ -

Gilje https://gilje.no/

Gilje https://gilje.no/

Your CONTACT

Interested? Then let's talk! About your customized comprehensive solution for coating construction elements.

Christian Streit

Wood|Building Materials